Planning and manufacturing of equipments for the extrusion of technical profiles in PVC, ABS, PC, Polyamide PA 6.6., WPC and Reinforced profiles.

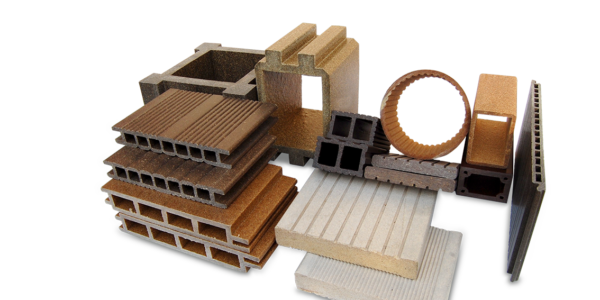

WPC

We have developed and tuned up an interesting innovative technological process consisting in the planning and in the manufacturing of equipment for the extrusion of WPC profile.

The WPC is obtained from the mixing of the wood sawdust or wood dust with Polypropylene, or Polyethylene, or Pvc, or ABS and it is employed for different applications in building, in general and industrial packaging and also in the automotive field.

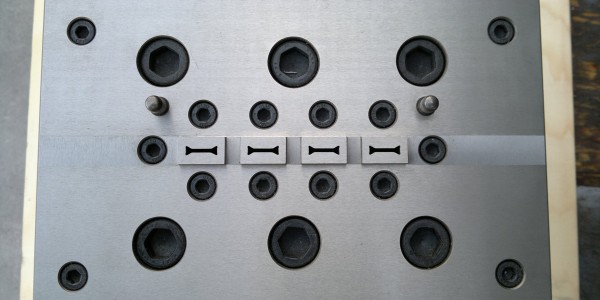

Polyamides PA 6.6

Since many years, our company has specialized in manufacturing of tools for the extrusion of bars for thermal cutting in PA 6.6. reinforced with fibreglass. This product has wide application in the aluminium doors and windows field.

We manufacture and plan complete equipments with 2 – 4 – 6 – 8 until to 12 exits, according to the hourly production required and the design of the profile.

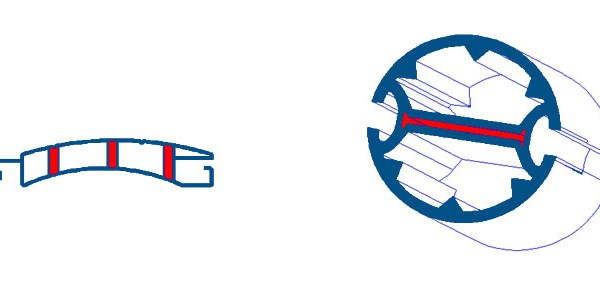

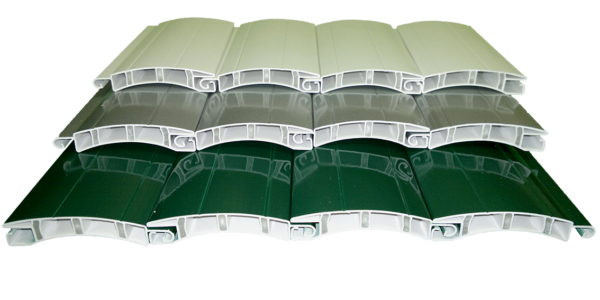

Reinforced profiles

We have filed a patent (n. 0001411276) for the construction of molds for the extrusion of profiles reinforced with a polymeric and non-metallic material. The two types of materials are extruded simultaneously thanks to a normal co-extrusion process. This method, used to avoid deformation of profiles exposed to sunlight and heat, is applicable not only to profiles for roller shutters but to any plastic material profile you want to reinforce.

To respond to the growing market demand for sustainable products made with renewable materials, respecting the environment, we have developed new technologies. We design and build equipment that uses recycled materials and extrude materials other than plastic which can be processed with the same technology as plastics.