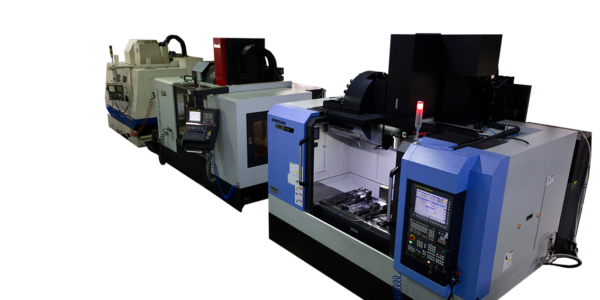

Romplast srl uses CNC machinery and wire-cutting EDM for the manufacturing of the tools for extrusion

All the production process, from the planning to the manufacturing and the test of the tools is carried out inside the company.

Phase 1

Preliminary study

The planning of the dies and calibrators is carried out in our technical office, starting both from drawings of the profiles supplied by customer and both from our drawings studied in close collaboration with customer in the way to respect his exigencies and the production constraints.

To this preliminary phase follows the real planning, that defines the geometry of the tool and the working phases of the raw steel block from which must be obtained the final mould. Since from 80’s, our technical office has been equipped with CAD/CAM systems that have been always updated to achieve the highest correctness and precision.

Phase 2

Processing

The manufacturing of the tool is carried out using CNC machinery at highest precision: machining centres, wire-cutting and die-sinking EDM, micro-hole drilling. To this new equipments are placed side by side the traditional machinery (milling machines, grinding machine, drills) that must be necessary still used in the manufacturing process.

Of a particular importance are the finishing and the assembling phases that are still carried out patiently and skilfully by hand.

Phase 3

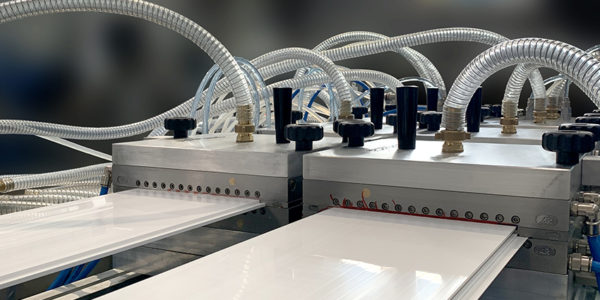

The test and the fine-tuning

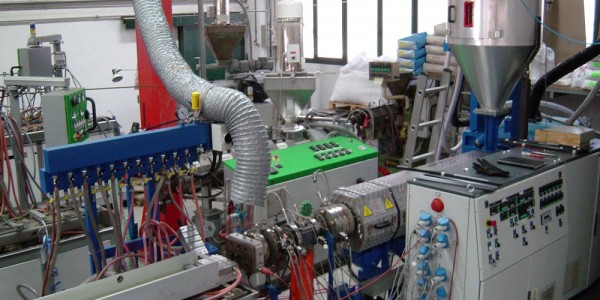

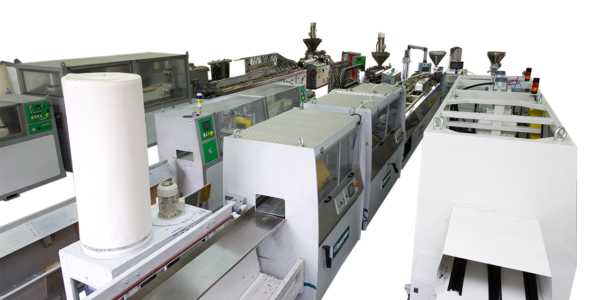

All equipment are tested and adjusted in our testing department equipped with single-screw and twin-screw extruders of the latest generation.

The final test is always carried out by our specialized staff in the presence of the customer by our workshop or, on specific request, by the customer’s company.

The technical know-how, the expertise and the efficiency of our staff to carry out the different working phases, enable to obtain dies and calibrators of high-quality, reliability and extrusion speed.